100% Natural Plant Fiber Product

100% natural, 100% natural return.

Product Features

HOME > Item description > Product Features

Unique product features of

FINECO whose R&D institute has developed innovative technology for manufacturing and top sealing bagasse containers.

The technology has been patented and can help you maximize the benefits of using bagasse containers thanks to the following features:

uses sugar cane pulp as raw material for their containers. However, thanks to our patented manufacturing technology containers not only match the solutions existing in the market in strength and durability, but also surpass them in some qualities such as storage longevity, as well as water and temperature resistance (please, refer to the features comparison file). Unlike other companies, FINECO does not use plastic and/or PLA coating because it was able to develop a technology that uses zero harmful chemical substances without compromising their product’s functionality, and even enhancing it comparing to its competitors.

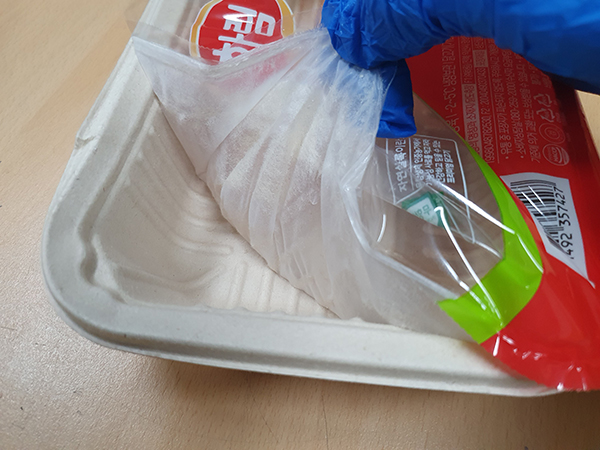

uses sugar cane pulp as raw material for their containers. However, thanks to our patented manufacturing technology containers not only match the solutions existing in the market in strength and durability, but also surpass them in some qualities such as storage longevity, as well as water and temperature resistance (please, refer to the features comparison file). Unlike other companies, FINECO does not use plastic and/or PLA coating because it was able to develop a technology that uses zero harmful chemical substances without compromising their product’s functionality, and even enhancing it comparing to its competitors.  developed the top sealing technology for bagasse containers which up till now only existed for plastic containers. The technology guarantees adhesion of top sealing film to the bagasse container. It allows leak-proof storage which is crucial when it comes to packaging of fresh meat and other liquid foods. After the container is unsealed the top plastic film can be easily and completely removed from the container. The peel-off function helps to separate the two parts (100% biodegradable bagasse container and recyclable plastic film) to redirect each one to their proper disposal channels. The combination of the two functions FINECO’s technology makes it the first one in the packaging industry to solve the problem of the top sealing film adhesiveness and recyclability at the same time.

developed the top sealing technology for bagasse containers which up till now only existed for plastic containers. The technology guarantees adhesion of top sealing film to the bagasse container. It allows leak-proof storage which is crucial when it comes to packaging of fresh meat and other liquid foods. After the container is unsealed the top plastic film can be easily and completely removed from the container. The peel-off function helps to separate the two parts (100% biodegradable bagasse container and recyclable plastic film) to redirect each one to their proper disposal channels. The combination of the two functions FINECO’s technology makes it the first one in the packaging industry to solve the problem of the top sealing film adhesiveness and recyclability at the same time.

Below, here is a short explanation about the product patents which is already summarized in the features comparison document as below.

Fineco product technology is based on 2 patents as explained below

- Patent 1: Disposable container using bagasse and hemicellulose and the manufacturing method thereof

- Patent 2: The peel-off Disposables Development of pulp container using Bagasse and Hemicellulose

- Actually, in the market, mainly bagasse and cellulose are used for eco-friendly /bagasse container which some time are not strong and safe enough regarding the content/product put in the container, and then PLA coating / plastic coating is used to make the container stronger and safer, for instance, which is not really healthy.

- So, here, regarding Fineco solution, the use of Hemicellulose which is a component where chemical properties have several qualities like providing several layers, etc… is the key because it helps to reinforce the bagasse container regarding the lack providing by using only cellulose.

- So regarding patent 2, Fineco top sealing film has 2 features which are the following:

- Adhesive / sticking / bonding function to stick the container and film together => this function is the only one available now for top sealing existing plastic film

- Peel-off function to separate the container and the film => this function is innovative and 1st in the history because it is not existing for existing top sealing plastic film

Note: Existing top sealing plastic film and plastic container because they are same material, stick very well together and because they are both recyclable such a peel-off function is not needed.

But a peel-off function is added value and meaning full with Fineco solution because it helps to separate 2 parts ( biodegradable & recyclable) which are not same material and redirected each one to their proper channel of destruction safely and prevent biodegradable & recyclable material to be destroyed together which is not eco-friendly or ESG, if it occurs.

Features comparison table of

| Containers’ Features |

FINECO Containers |

Other Bagasse Containers |

Plastic Containers |

|---|---|---|---|

| Raw materials |

|

|

|

| ESG (Environment, Social, Governance ) |

|

|

|

| Eco-friendly |

|

|

Not compliant / partially compliant

|

| Highly resistance / Water-proof, Oil-proof |

|

|

|

| Temperature (Heat and cold) resistance |

|

|

|

| Preservation (storing) time |

|

|

|

| Sturdy / Durable |

|

|

|

| Safety |

|

|

|

| Eco-friendly Coating |

|

|

|

| Eco-friendly Laminated film |

|

|

|

| High Quality of top sealing film |

|

|

|

| Transparence of top sealing film |

|

|

|

| Top sealing film tech |

|

|

|

| Recyclability |

|

|

|

| Certifications |

|

|

|